Crystal Clear Epoxy Resin for Super Gloss Coating on Tabletops

·The most advanced epoxy coating on the market.

·Ultra Clear epoxy boasts the most advanced level of shine, gloss, reflectivity, clarity and depth, and it locks in those optical qualities forever. The most sophisticated system of synthetic polymeric-based protection available. Our Commercial-grade epoxy is engineered specifically for Bar Tops, Tabletops & Countertops.

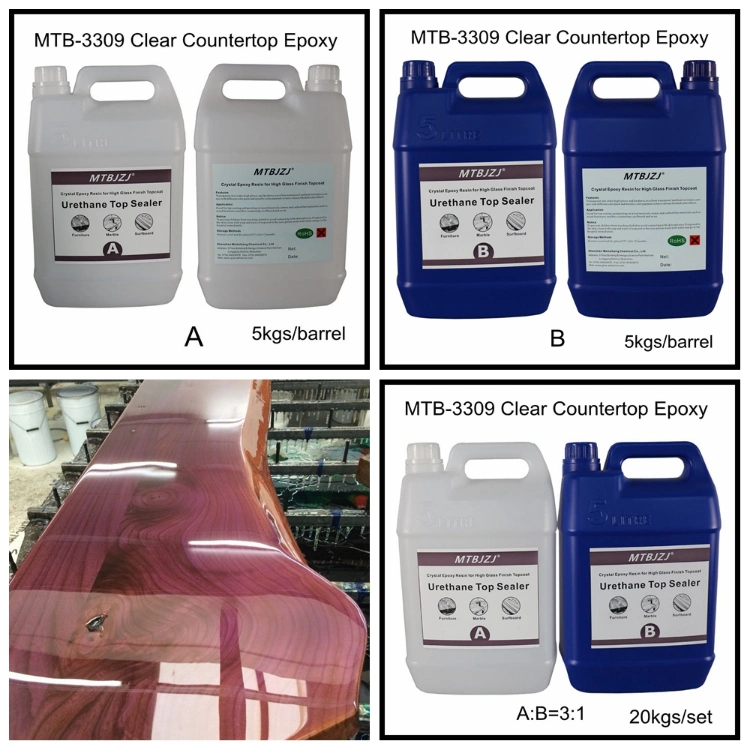

·Can make the whole coating project to determine the role of color, luster bright, smooth and lively, the abrasion resistance, acid and alkali resistance, oil resistance, resistance to water, dust, etc. In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 3:1.To make the finished top coat much more glossy and brighter.

Crystal Clear Epoxy Resin for Super Gloss Coating on Tabletops

Crystal Clear Epoxy

Unlike most epoxy resins,our unique blend of polycarbons produces a completely transparent dinish that will never yellow,fade or crack with time.It is a product you can trust.

Extremely Durable& Self-Leveling

MTB-3309 Clear Countertop epoxy self-levels to 1/8",creating a virtually indestructible surface. The result is a crystal clear, brilliant surface that accentuates the material below it. Truly beautiful to behold.

Scratch Resilient& Maintenance Free

MTB-3309 Clear countertop epoxy is specially formulated to resist scratching and provide long lasting maintenance free protection for your surface.

100% VOC Free

MTB-3309 Clear countertop epoxy is free from volatile organic compounds and is compliant with all environmental requirements implemented by international organizations such as the Environmental Protection Agency and the World Health Organization.

Easy Do it Yourself Once-Coat System

MTB-3309 Clear countertop epoxy self levels at 3mm(that is 1/8").That is twice thick as other countertop epoxy on the market. Our one coat epoxy system will save your time and money. Our simple 3-steps process(measure, mix and pour) is easy enough for anyone to do and the end result will be spectaculer! You do not have to be a professional to achieve a professional look. We provide easy to read instructions and videos that will show you exactly what to do.

Crystal Clear Epoxy Resin for Super Gloss Coating on Tabletops

Crystal Clear Epoxy Resin for Super Gloss Coating on TabletopsMake your surface to come to life with rich, vibrant detail the most striking contrast ever. Engineered to work on virtually any surface:

| - Wood - Laminate - Metal - Photos - Concrete - Corian | - Pennies - Shells - Stainless Steel - Marble - Bottle Caps - Sand | - Ceramic - Porcelain - Stickers - Paper -Granite - Bamboo |

Crystal Clear Epoxy Resin for Super Gloss Coating on Tabletops

Item | MTB-3309(A) | MTB-3309(B) |

Appearance | Clear Liquid | Clear Liquid |

Mix Ratio by weight | 3:1 | |

Operation Time(H) | 30mins | |

Curing Time(H) | 3Hrs | |

Cured Time(D) | 2Days | |

Solid Content(%) | 100 | |

Levelling roperty(Grade) | 80 | |

Operation Method | Roller /Self-level | |

Operation Temperature | 5ºC~40ºC | |

Coverage Data(1mm) | 0.8kgs/sqm | |

Mixed Viscosity(Cps) | 700-1100 | |

Compressive Strength | 55 | |

Wear resistance (mg) | 28 | |

Fineness (μm) | 40~80 | |

Shelf Life (M) | 12 | |

Package | 16oz/set, 1 Gallon/set, 2 Gallon/set and 20L /set ,accept OEM&ODM | |

Crystal Clear Epoxy Resin for Super Gloss Coating on Tabletops

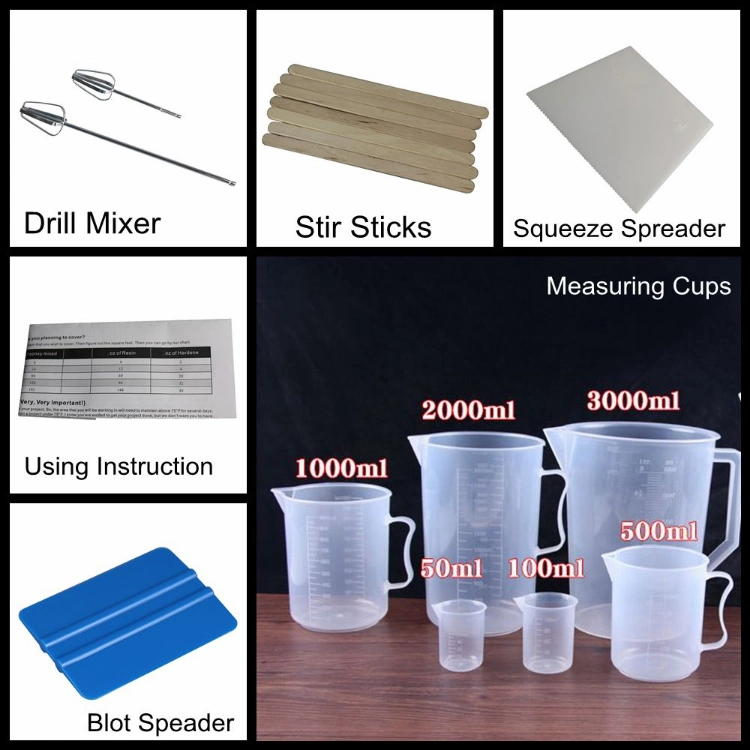

How to use MTB-3309 Ultra Clear Table Top Epoxy Coating /Extremely Durable Table Top Finish?

Step 1: Measure EpoxyMTB-3309 Clear Epoxy is a two-part, epoxy coating that is mixed at a 3 to 1 ratio. Pour an equal amount of hardener and resin into a new container. It is important that you use a new container for each batch that you mix so that the next batch does not get contaminated from the remnants of curing epoxy in the previous container.

Step 2: Mix Epoxy

Step 3: Paint on a Seal Coat of Epoxy

Step 4: Pour Epoxy Flood Coat

*Multiple flood coats can be applied to cover over embedded objects. Just pour a new flood coat every 4 hours.

Step 5: Pop Air Bubbles with a Plumber's Torch or Heat Gun

Finished Project

Working Temperature of MTB-3309 Clear Ultra Clear Table Top Epoxy Coating /Extremely Durable Table Top Finish

The working room temperature must be above 75 degrees, several hours prior to mixing the epoxy. We recommend that the product be brought inside and acclimated to room temperature, as it will be cold during winter shipping months. Use space heaters if necessary to ensure the temperature remains above 75 degrees in cold areas, such as garages and basements. It is extremely important that the temperature remain above 75 degrees for a full 72 hours, in order for the epoxy to cure. High or low humidity and higher temperatures (75-110 degrees) are perfectly fine for curing; the epoxy cures much faster with higher temperatures.

Crystal Clear Epoxy Resin for Super Gloss Coating on Tabletops

We have below packages for you choice,

--16oz kit

--320z kit

--1gallon kit

--2gallons Kit

--20kgs Kit

Contact Supplier for more details