Grey Silicone Rubber Cold Shrink Tube

Company Profile

Description

Silicone Rubber Cold Shrink Tubing is made of special purpose silicone rubber with a high shrink ratio and excellent physical and mechanical properties like slab and prick resistance. It reliably seals electrical connections of electric communications and cable televisions against water and moisture and effectively insulates wire and cable connections or joints and other electrical connections etc.

Features

² Continuous operating temperature: -60~200degrees C

² Suits for an extensive range of cable sizes because of the shrinkage

² Retains its resiliency and pressure even after prolonged years of ageing and exposure, seals tight against moisture and water

² Good weather resistance, ozone ageing, ultraviolet and salt mist corrosion resistance, performs stably under long-period exposure to the sun

² Excellent tear resistance

² Simple installation, requires no special heating tools, and adhesive to seal the connections

² Standard color: Black

Technical Data

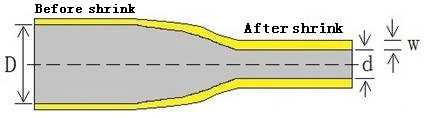

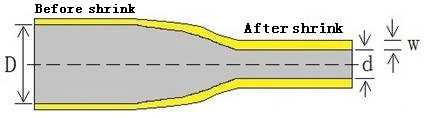

Structure

Dimensions

Certificate

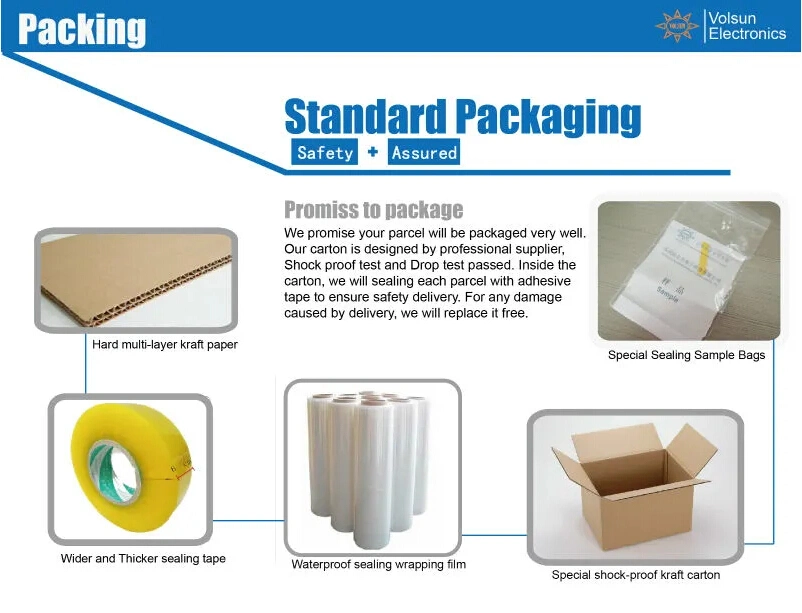

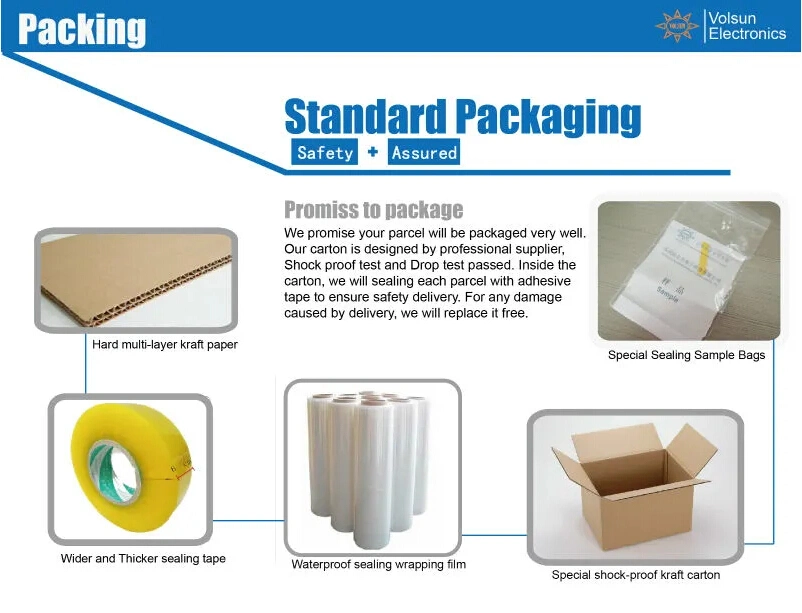

Packing

Customers & Exhibitions

Company Profile

Description

Silicone Rubber Cold Shrink Tubing is made of special purpose silicone rubber with a high shrink ratio and excellent physical and mechanical properties like slab and prick resistance. It reliably seals electrical connections of electric communications and cable televisions against water and moisture and effectively insulates wire and cable connections or joints and other electrical connections etc.

Features

² Continuous operating temperature: -60~200degrees C

² Suits for an extensive range of cable sizes because of the shrinkage

² Retains its resiliency and pressure even after prolonged years of ageing and exposure, seals tight against moisture and water

² Good weather resistance, ozone ageing, ultraviolet and salt mist corrosion resistance, performs stably under long-period exposure to the sun

² Excellent tear resistance

² Simple installation, requires no special heating tools, and adhesive to seal the connections

² Standard color: Black

Technical Data

| Properties | Typical Data | Test Method |

| HS | 45A | ASTM D 2240 |

| Tensile Strength | 9.8MPa | GB/T 528 |

| Elongation at break | 840% | GB/T 528 |

| Tear Strength | 39kN/m | ASTM D 624 |

| Dielectric Strength | 23kV/mm | ASTM D 149 |

| Volume Resistivity | 9×10 15 Ω.cm | ASTM D 257 |

Structure

Dimensions

| Volsun Spec. | Expanded (mm) | Min. Cable Outer Diameter (mm) | Max. Cable Outer Diameter (mm) | Max. Cable Outer Diameter (mm) |

| VS25-2.5 | ID25 | 7.3 | 21.0 | 63.5 |

| VS25-3.2 | ID25 | 7.3 | 21.0 | 81.3 |

| VS25-7 | ID25 | 7.3 | 21.0 | 178 |

| VS25-8 | ID25 | 7.3 | 21.0 | 203 |

| VS25-11 | ID25 | 7.3 | 21.0 | 279 |

| VS28-5 | ID28 | 6.0 | 25.0 | 125 |

| VS28-6 | ID28 | 6.0 | 25.0 | 150 |

| VS32-8 | ID32 | 11.0 | 28.0 | 203 |

| VS32-11 | ID32 | 11.0 | 28.0 | 279 |

| VS32-12 | ID32 | 11.0 | 28.0 | 300 |

| VS35-5 | ID35 | 10.5 | 30.0 | 130 |

| VS35-7 | ID35 | 10.5 | 30.0 | 180 |

| VS35-9 | ID35 | 10.5 | 30.0 | 229 |

| VS35-10 | ID35 | 10.5 | 30.0 | 260 |

| VS35-11 | ID35 | 10.5 | 30.0 | 279 |

| VS35-12 | ID35 | 10.5 | 30.0 | 300 |

| VS40-8 | ID40 | 11.9 | 34.0 | 203 |

| VS40-10 | ID40 | 11.9 | 34.0 | 250 |

| VS40-12 | ID40 | 11.9 | 34.0 | 305 |

| VS40-16 | ID40 | 11.9 | 34.0 | 406 |

| VS40-18 | ID40 | 11.9 | 34.0 | 450 |

| VS45-6 | ID45 | 13.5 | 39.0 | 152 |

| VS45-7 | ID45 | 13.5 | 39.0 | 178 |

| VS45-8 | ID45 | 13.5 | 39.0 | 203 |

| VS45-10 | ID45 | 13.5 | 39.0 | 254 |

| VS45-12 | ID45 | 13.5 | 39.0 | 305 |

| VS53-4 | ID53 | 24.0 | 49.0 | 100 |

| VS53-6 | ID53 | 24.0 | 49.0 | 152 |

| VS53-10 | ID53 | 24.0 | 49.0 | 250 |

| VS53-12 | ID53 | 24.0 | 49.0 | 305 |

| VS53-18 | ID53 | 24.0 | 49.0 | 457 |

| VS53-20 | ID53 | 24.0 | 49.0 | 500 |

| VS70-5 | ID70 | 31.0 | 67.8 | 125 |

| VS70-6 | ID70 | 31.0 | 67.8 | 152 |

| VS70-14 | ID70 | 31.0 | 67.8 | 350 |

Certificate

Packing

Customers & Exhibitions